| ||||

| ||||

| ||||

home / about the artist / stoneboat series / lipwork series / metaphorical presences / landscapes / multi-element installation pieces / recent works

technical processes / thumbnail galleries / Cortona foundry / Finland stone carving / recommended reading / all in the family / links page

www.dondougan.com

DON DOUGAN

PNEUMATIC HAMMERS

TRADITIONAL PROCESSES

| ||||

| ||||

| ||||

| ||||

| ||||

The Trow and Holden Company in Vermont introduced the Pneumatic Carving Hammer to the

stoneworking industry in 1890, and the company

continues to make top quality tools for the stone carver.

Other companies who manufacture Carving Hammers are

the Dallet Company (now defunct), Bicknell Manufacturing

(Maine), and Cuturi (Italy).

| ||||

The female quick-connect fitting is attached to the discharge end of incoming supply hose.

another type of air hammer

Note the in-line air valve fitted to the small finishing hammer (at left) which allows minute adjustments of the air feed for greater control.

The pneumatic hammer has only

one moving part — the piston (the

darker crosshatched portion in the cut-

away drawing at right) that travels

back-and-forth in the body of the

tool and strikes the end of the chisel.

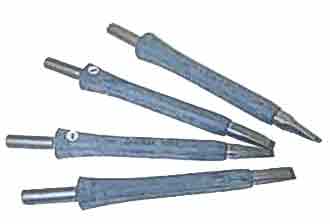

Another type of pneumatic hammer that is

more commonly available than the stone

carving hammers above. These pistol-grip

type hammers (at right) are made for ripping

and hammering sheet metal, and minor

demolition work of masonry. The least

expensive versions cost about a tenth of the

price of the standard stone carving

hammers, though the value of a good quality

tool of this type will be more - though still

less than a hammer designed for stonecarving.

The shank of the chisels made to fit in these

hammers is smaller than those that fit regular

carving hammers, and the chisel also has a

shaped flange that fits the spring holder on

the end of the hammer. The range of styles

of chisels available to fit these hammers is

very limited: a point, a flat chisel, a

hammering face, and several sheet-metal

ripping styles not pictured.

More commonly available than the stone

carving hammers above, these pistol-grip

type hammers (at right) are made for ripping

and hammering sheet metal, and minor

demolition work of masonry.

NOTE: The three tooth chisels pictured were my

modifications from straight flat chisels.

| ||||

| ||||

Though a main shut-off valves should be attached to the compressor, the installation of quick-connect fittings on the in-line supply valve (as on the example shown at right) allows a greater flexibility when interchanging hoses and different tools on the same supply line.

Though not an essential fitting, swiveling-elbow joints like this allow the carver a much greater degree of freedom of movement while attached to the sometimes heavy and awkward rubber supply hose from the compressor.

This example has both male and female quick-connects fitted so it can be used or removed easily as needed.

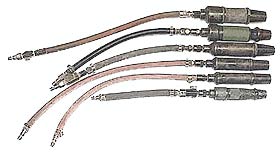

The pneumatic hammer comes in several sizes and types, the most common of which accepts chisels with a 1/2" diameter shank. The size and type of hammer is varied to accommodate the needs of the carver and type of work being performed.

The larger of the two hammers at left is used primarily for roughing-out work on harder varieties or larger blocks of stone, while the smaller 'short-stroke' hammer at left allows a much greater degree of control for the carver in the later stages of work when carving finishing details.

The size of pneumatic carving hammer to use

will depend not only on the type of carving and

the hardness of the stone being carved, but also

on the balance and weight in the user's hands.

For general work I find the 3.2 lb. long stroke

Dallet hammer to be the best compromise

between carving power and comfort. And for

detail carving, after buying the 2.2 lb. Trow and

Holden 1/2" short-stroke I rarely reach for the

small long-stroke hammers anymore.

4.6 lbs.

Cuturi

4.3 lbs.

Dallet

3.2 lbs.

Dallet

2.4 lbs.

long stroke

2.1 lbs.

long stroke

2.2 lbs.

Trow & Holden

short stroke

The air compressor and the rubber supply hoses should have quick-connect fittings at both the supply and discharge ends of the hose.

The quick-connects allow the various air driven tools to be switched easily as the work requires.

Pneumatic hammers are difficult to wear-out — four of the six hammers below were bought secondhand from carver's who told me they bought them in the1920s and '30s. These old hammers work almost as well as the Trow and Holden and Cuturi hammers purchased new in 1991.

The corresponding male quick-connect fitting at the end of the whip attached to the intake on the pneumatic tool, or to the intake end of a supply hose.

The air hammers should be attached to a short length of rubber air hose (called a whip) to prevent the hammer vibrations from damaging the quick-connect fittings. The exact length of the whip should provide an easily accessible and comfortable location for the connections and in-line air control valve while working.

| ||||

| ||||

To the novice carver these hammers are very appealing for a couple of reasons — the relatively low initial expense and the familiar switch and grip style similar to an electric drill. But I have found that if the carving student has the option of becoming familiar with both styles of hammer, it is usually this pistol-grip type of hammer that is discarded in favor of the regular stone carving style hammer. Though these pistol-grip hammers are certainly serviceable, for my own work it comes down to the greater degree of control afforded by the loose socket and the generally longer shank-length of the chisels made to fit those regular stone carving hammers.

On the other hand, in French stonecarving supply stores

there is a similar type of carving hammer to this (the shank

is differently shaped)

that is widely used by

numerous monument

carving shops in France.

(at left)

Lettering chisels to fit the French pneumatic

carving hammer (at right)

| ||||

And finally, for the carver who wants both the versatility of the loose socket Carving Hammer and the pistol grip style, an Italian design combines both into one tool. The one pictured (at left) is comparable in size and power to the mid-size hammer (3.2 lb. Dallet), though it weighs a bit more because of the handle.

NOTE: hammer is shown with the typical Italian-style of quick-connect which joins by a screw-twist method rather than the snap-on type shown above.

For those carvers who work in a small scale or in need the flexibility of a small tool to get into tight areas there is made a small pneumatic carving hammer — sometimes called a pneumatic pen — that can be held in one hand much like a writing pen, though using it with two hands will allow a greater degree of control.

The example pictured is an Italian design, though there are similar designs made by American manufacturers.

| ||||